Detailed Description

Data Structures | |

| class | RpmCalculator |

Enumerations | |

| enum | spinning_state_e { STOPPED , SPINNING_UP , CRANKING , RUNNING } |

Functions | |

| void | rpmShaftPositionCallback (trigger_event_e ckpSignalType, uint32_t trgEventIndex, efitick_t edgeTimestamp) |

| Shaft position callback used by RPM calculation logic. | |

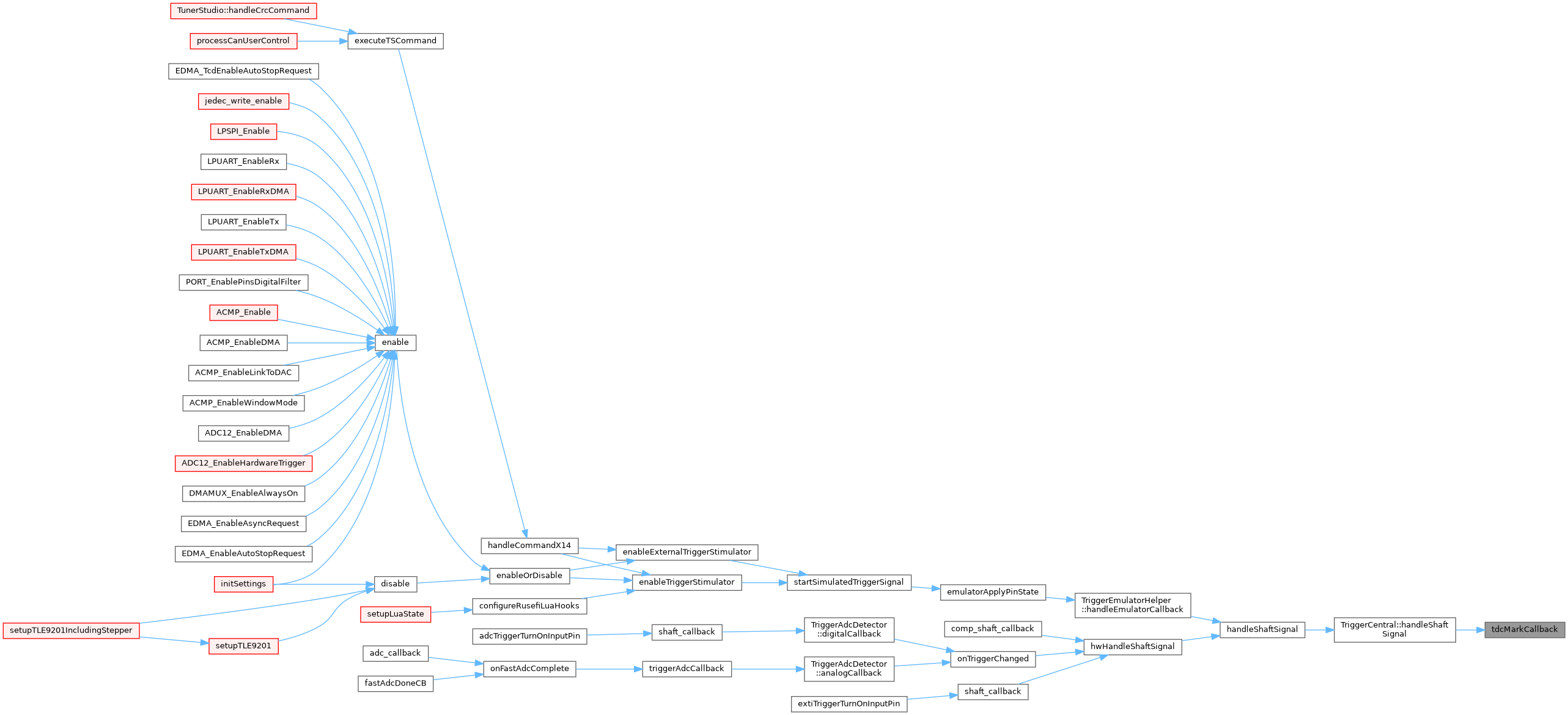

| void | tdcMarkCallback (uint32_t trgEventIndex, efitick_t edgeTimestamp) |

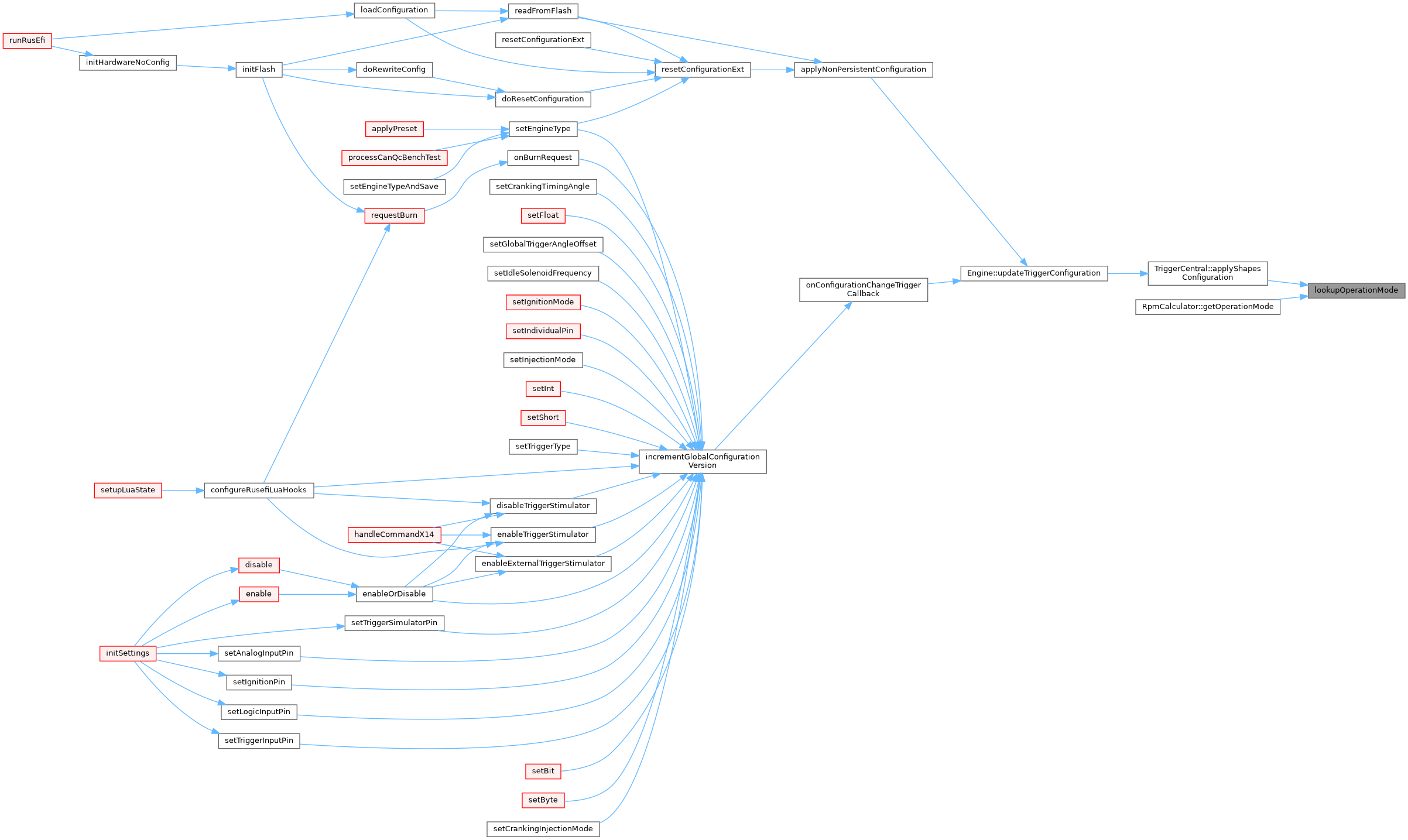

| operation_mode_e | lookupOperationMode () |

| efitick_t | scheduleByAngle (scheduling_s *timer, efitick_t nowNt, angle_t angle, action_s const &action) |

Enumeration Type Documentation

◆ spinning_state_e

| enum spinning_state_e |

Definition at line 19 of file rpm_calculator.h.

Function Documentation

◆ lookupOperationMode()

| operation_mode_e lookupOperationMode | ( | ) |

Definition at line 53 of file rpm_calculator.cpp.

Referenced by TriggerCentral::applyShapesConfiguration(), and RpmCalculator::getOperationMode().

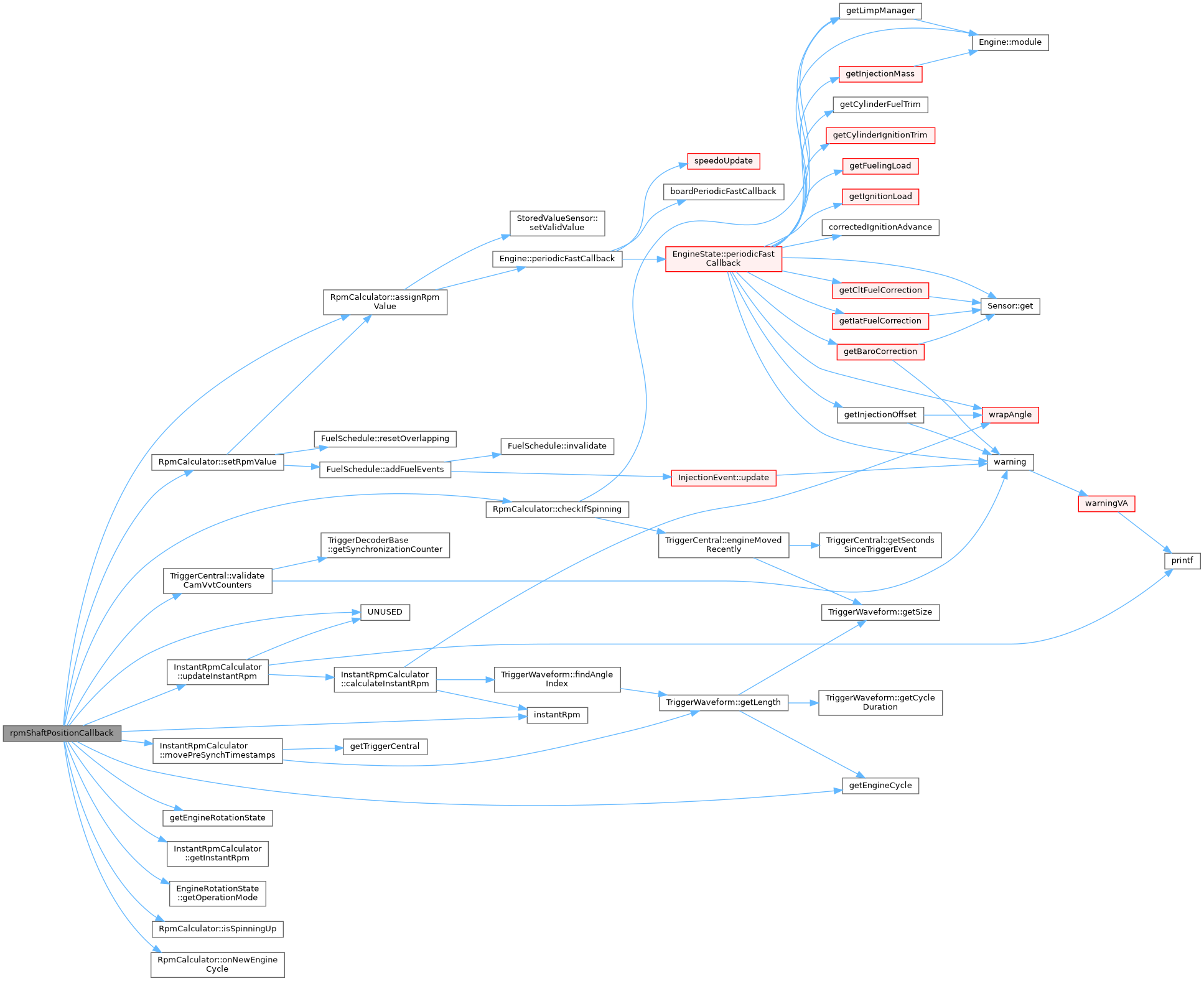

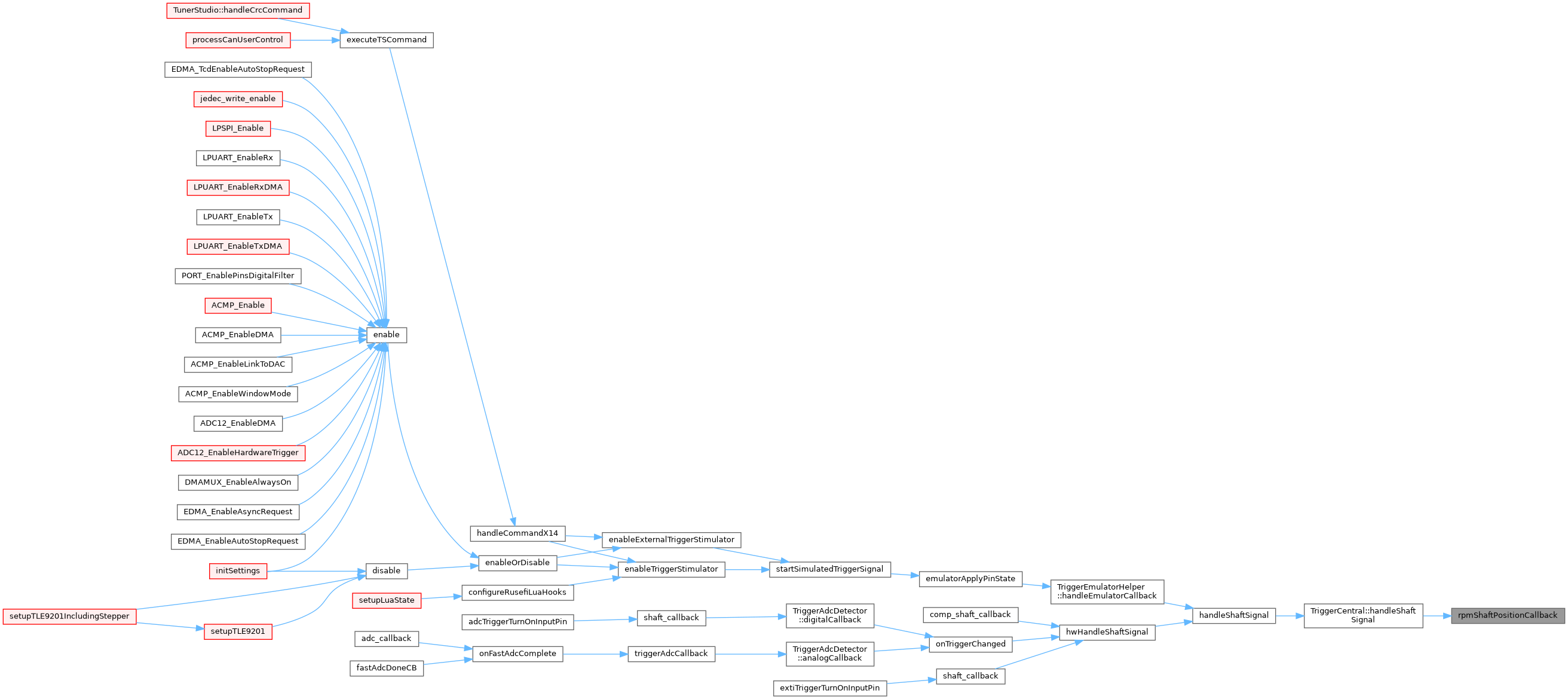

◆ rpmShaftPositionCallback()

| void rpmShaftPositionCallback | ( | trigger_event_e | ckpSignalType, |

| uint32_t | trgEventIndex, | ||

| efitick_t | nowNt | ||

| ) |

Shaft position callback used by RPM calculation logic.

This callback should always be the first of trigger callbacks because other callbacks depend of values updated here. This callback is invoked on interrupt thread.

Four stroke cycle is two crankshaft revolutions

We always do '* 2' because the event signal is already adjusted to 'per engine cycle' and each revolution of crankshaft consists of two engine cycles revolutions

Definition at line 253 of file rpm_calculator.cpp.

Referenced by TriggerCentral::handleShaftSignal().

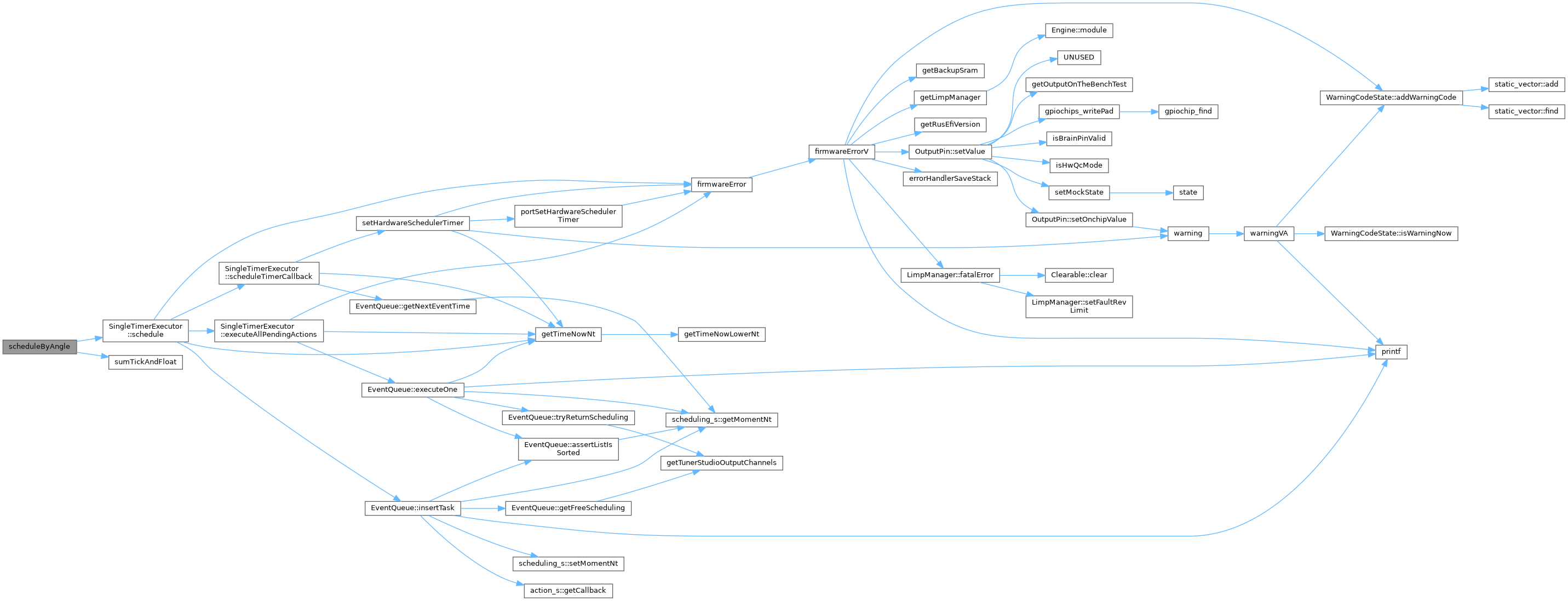

◆ scheduleByAngle()

| efitick_t scheduleByAngle | ( | scheduling_s * | timer, |

| efitick_t | nowNt, | ||

| angle_t | angle, | ||

| action_s const & | action | ||

| ) |

- Returns

- tick time of scheduled action

Schedules a callback 'angle' degree of crankshaft from now. The callback would be executed once after the duration of time which it takes the crankshaft to rotate to the specified angle.

- Returns

- tick time of scheduled action

Definition at line 381 of file rpm_calculator.cpp.

Referenced by fireSparkAndPrepareNextSchedule(), MapAveragingModule::onEnginePhase(), Engine::onSparkFireKnockSense(), InjectionEvent::onTriggerTooth(), HpfpController::pinTurnOn(), TriggerScheduler::scheduleEventsUntilNextTriggerTooth(), TriggerScheduler::scheduleOrQueue(), scheduleSparkEvent(), startAveraging(), tdcMarkCallback(), and turnSparkPinHighStartCharging().

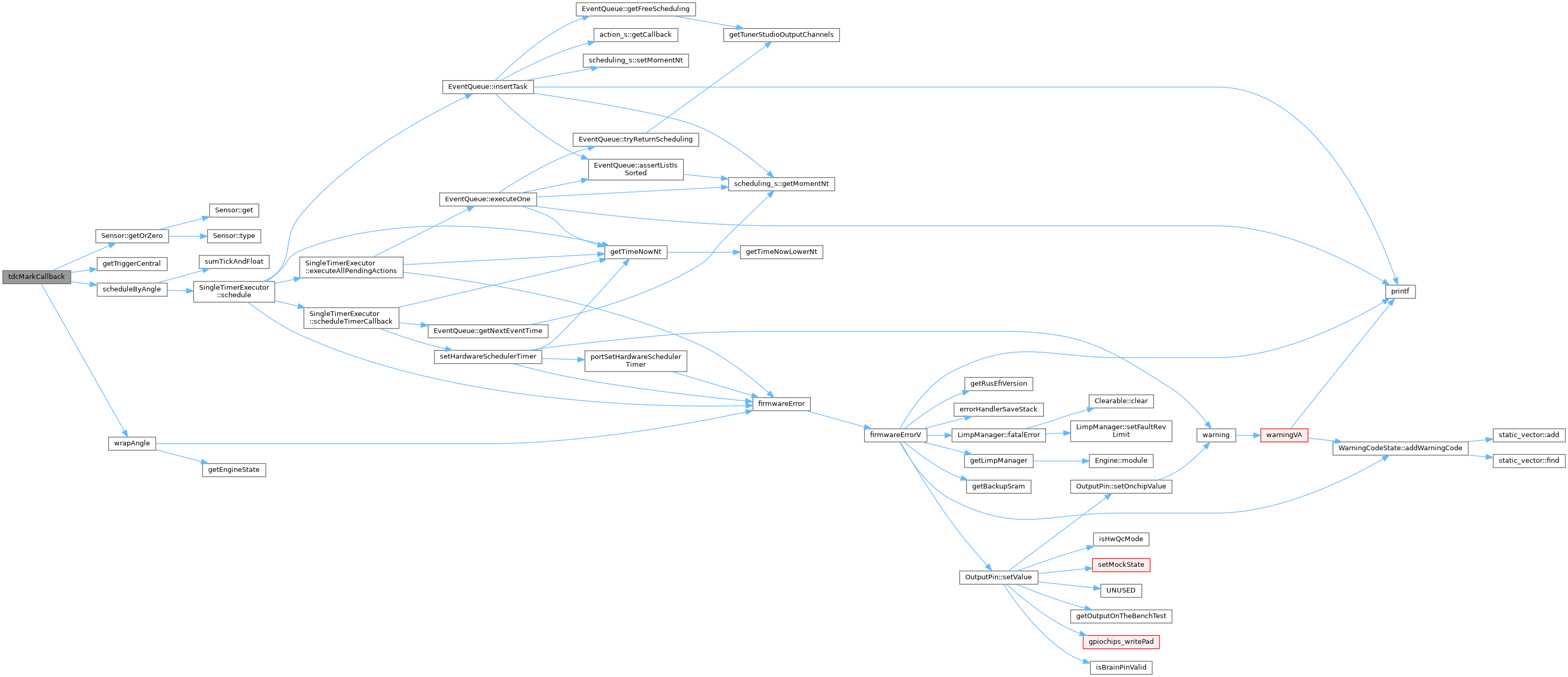

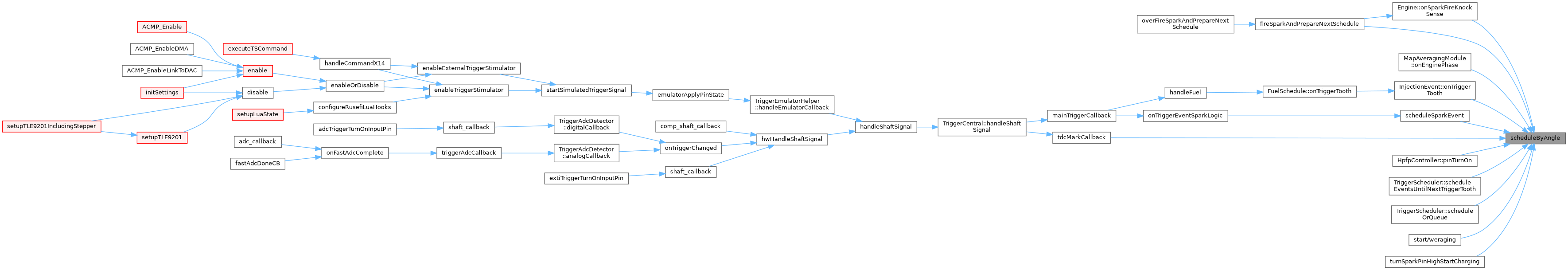

◆ tdcMarkCallback()

| void tdcMarkCallback | ( | uint32_t | trgEventIndex, |

| efitick_t | nowNt | ||

| ) |

This trigger callback schedules the actual physical TDC callback in relation to trigger synchronization point.

Definition at line 349 of file rpm_calculator.cpp.

Referenced by TriggerCentral::handleShaftSignal().