Detailed Description

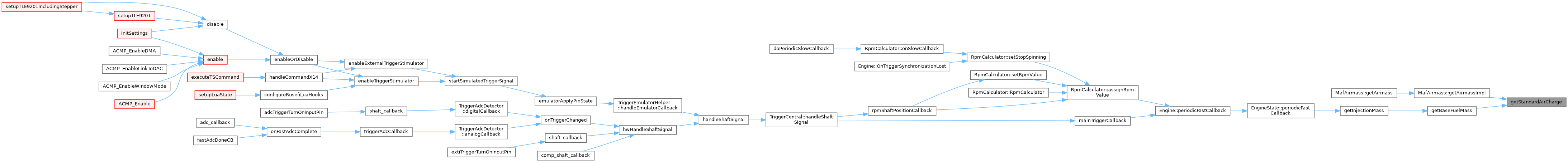

Fuel amount calculation logic.

- Date

- May 27, 2013

This file is part of rusEfi - see http://rusefi.com

rusEfi is free software; you can redistribute it and/or modify it under the terms of the GNU General Public License as published by the Free Software Foundation; either version 3 of the License, or (at your option) any later version.

rusEfi is distributed in the hope that it will be useful, but WITHOUT ANY WARRANTY; without even the implied warranty of MERCHANTABILITY or FITNESS FOR A PARTICULAR PURPOSE. See the GNU General Public License for more details.

You should have received a copy of the GNU General Public License along with this program. If not, see http://www.gnu.org/licenses/.

Definition in file fuel_math.cpp.

Variables | |

| ve_Map3D_t | veMap |

| static mapEstimate_Map3D_t | mapEstimationTable {"mape"} |

| static SpeedDensityAirmass | sdAirmass (veMap, mapEstimationTable) |

| static MafAirmass | mafAirmass (veMap) |

| static AlphaNAirmass | alphaNAirmass (veMap) |

| static Hysteresis | stage2Hysteresis |

Function Documentation

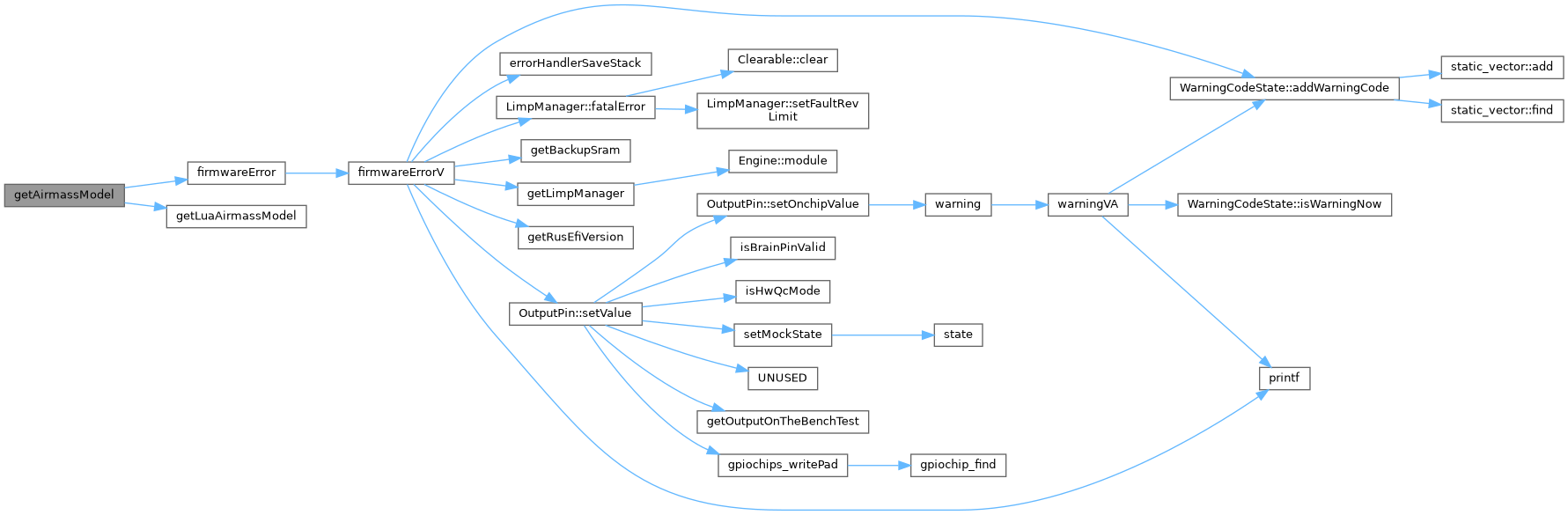

◆ getAirmassModel()

| AirmassModelBase * getAirmassModel | ( | engine_load_mode_e | mode | ) |

Definition at line 156 of file fuel_math.cpp.

Referenced by getBaseFuelMass(), and lua_getAirmass().

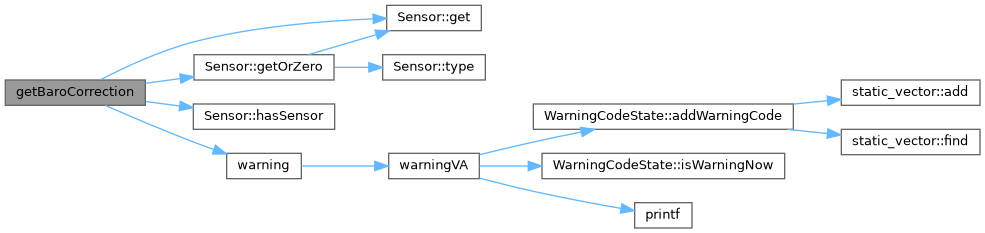

◆ getBaroCorrection()

| float getBaroCorrection | ( | ) |

Definition at line 429 of file fuel_math.cpp.

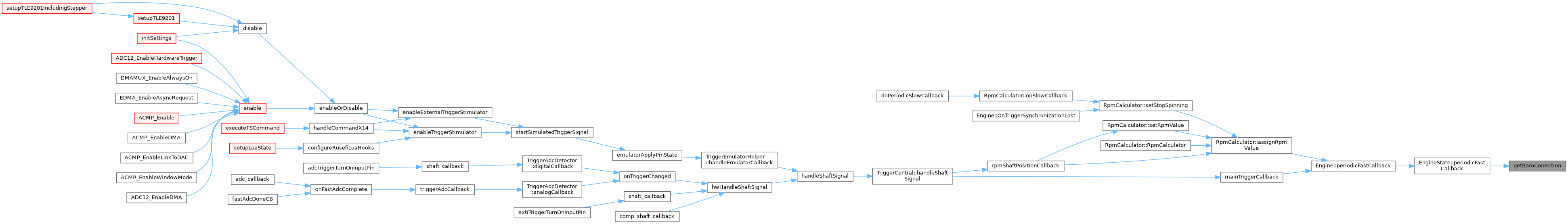

Referenced by EngineState::periodicFastCallback().

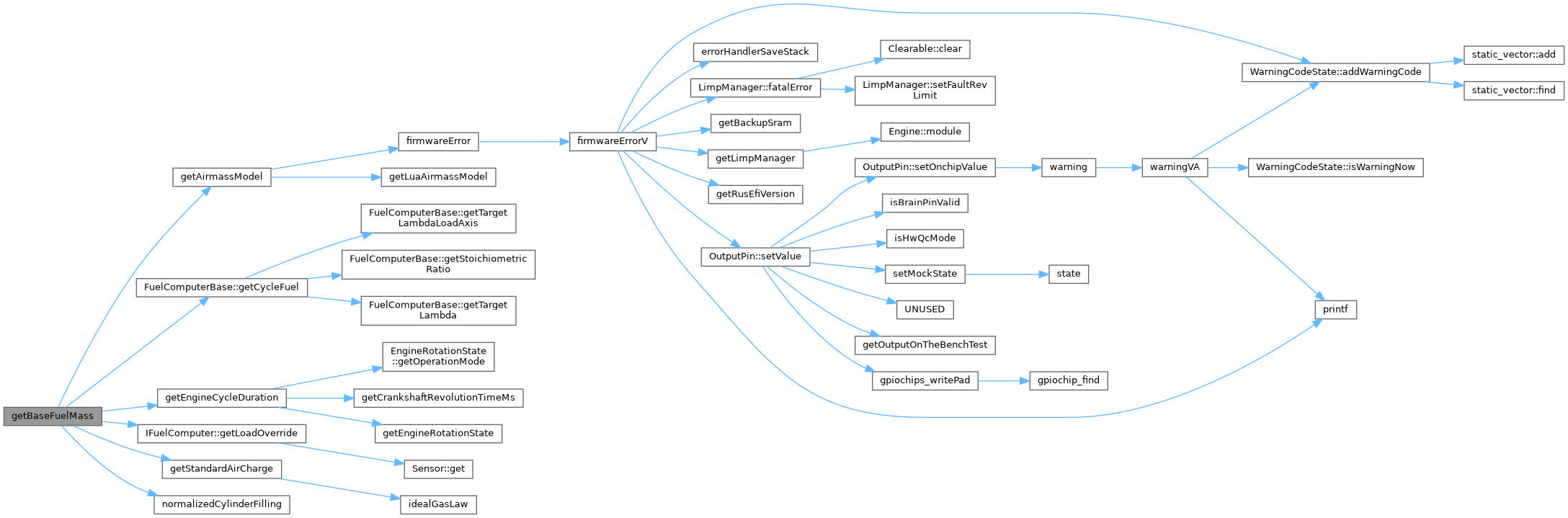

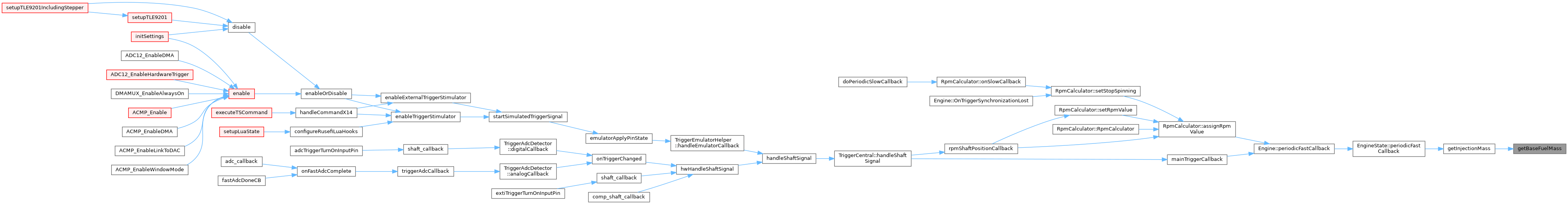

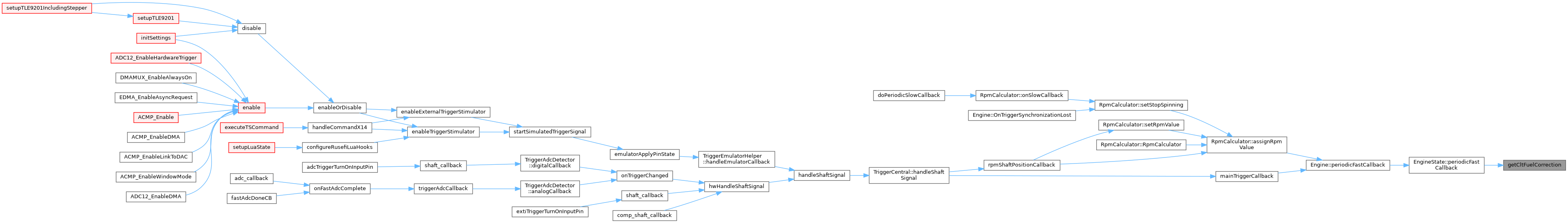

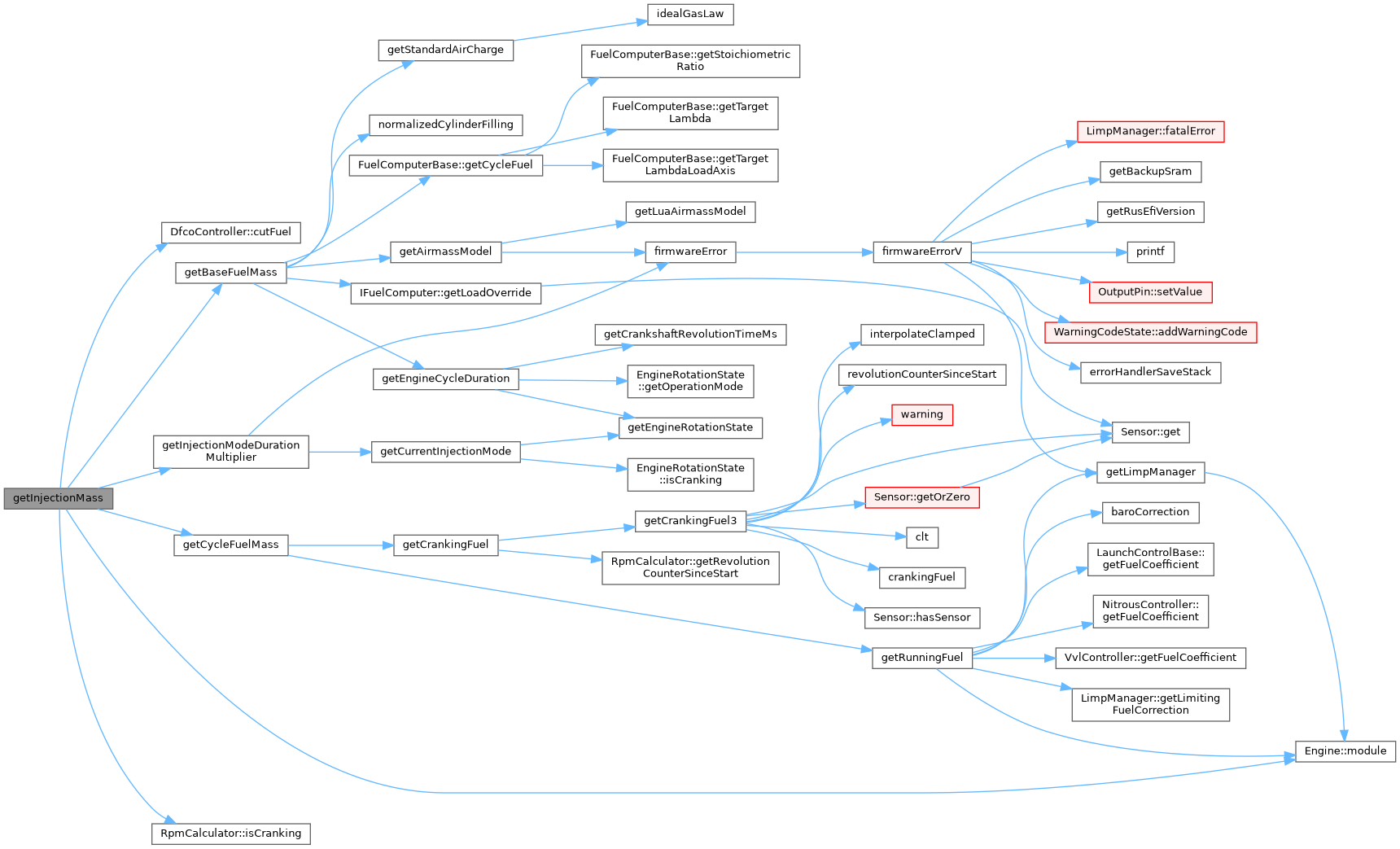

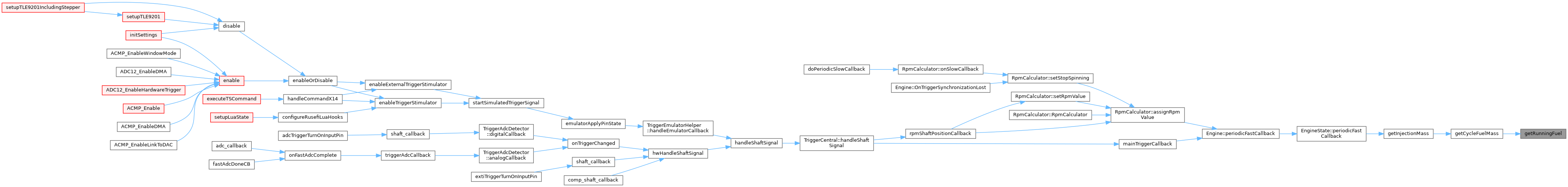

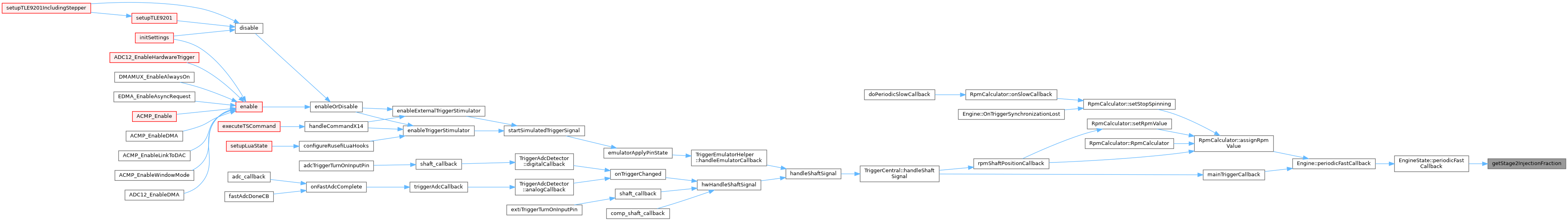

◆ getBaseFuelMass()

Definition at line 183 of file fuel_math.cpp.

Referenced by getInjectionMass().

◆ getCltFuelCorrection()

| float getCltFuelCorrection | ( | ) |

Engine warm-up fuel correction.

Definition at line 386 of file fuel_math.cpp.

Referenced by EngineState::periodicFastCallback().

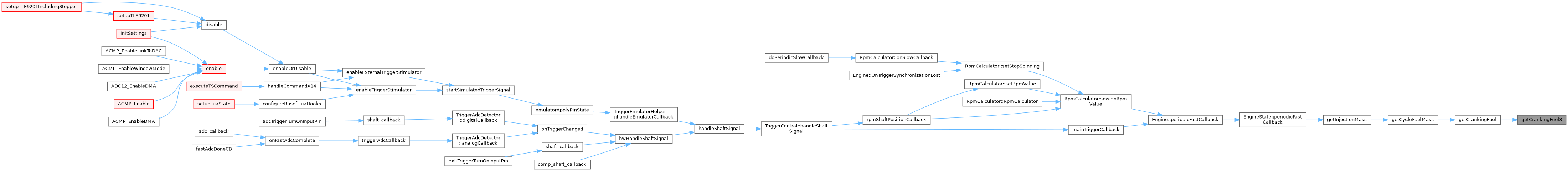

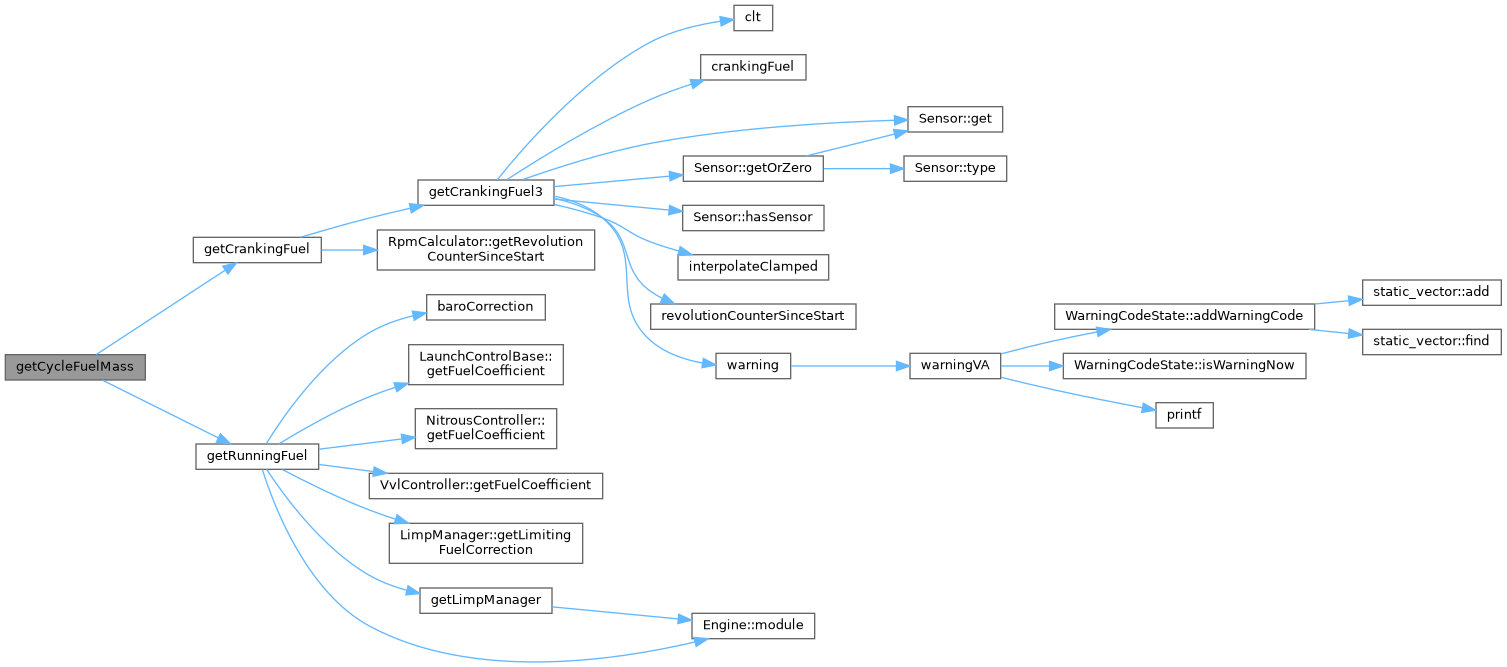

◆ getCrankingFuel()

- Returns

- Duration of fuel injection while craning

Definition at line 472 of file fuel_math.cpp.

Referenced by getCycleFuelMass().

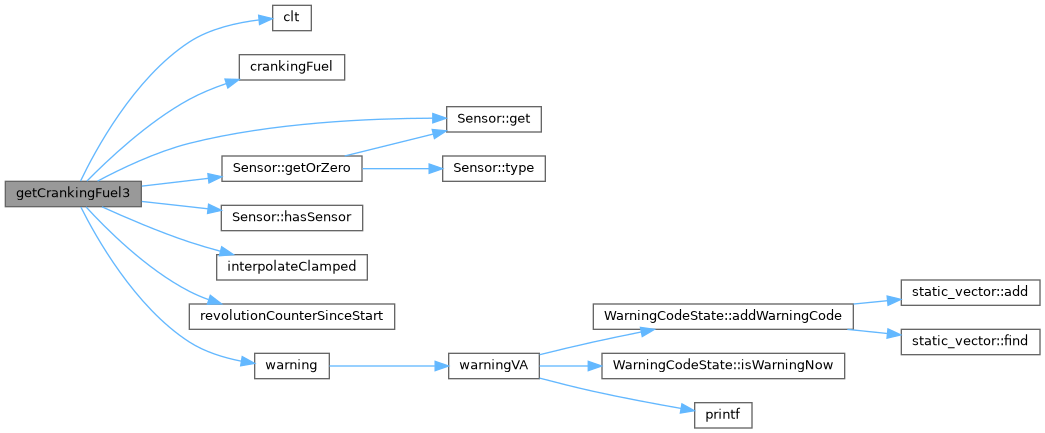

◆ getCrankingFuel3()

Cranking fuel is different depending on engine coolant temperature If the sensor is failed, use 20 deg C

Definition at line 42 of file fuel_math.cpp.

Referenced by getCrankingFuel().

◆ getCycleFuelMass()

Definition at line 300 of file fuel_math.cpp.

Referenced by getInjectionMass().

◆ getCylinderFuelTrim()

| PUBLIC_API_WEAK_SOMETHING_WEIRD float getCylinderFuelTrim | ( | size_t | cylinderNumber, |

| float | rpm, | ||

| float | fuelLoad | ||

| ) |

Definition at line 491 of file fuel_math.cpp.

Referenced by EngineState::periodicFastCallback().

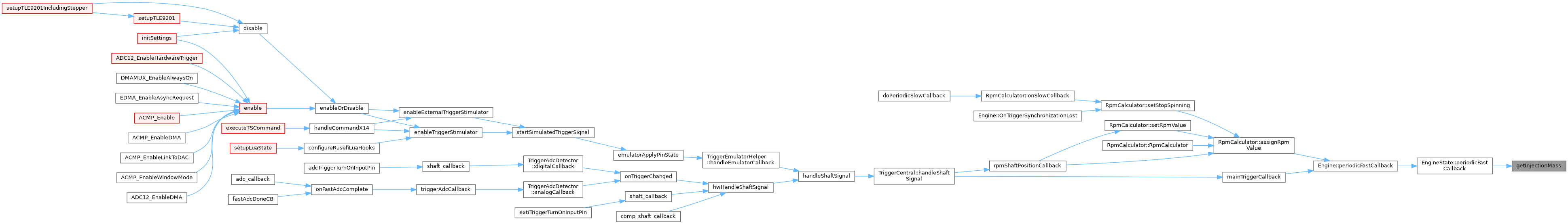

◆ getFuelALSCorrection()

Definition at line 451 of file fuel_math.cpp.

Referenced by AntilagSystemBase::update().

◆ getIatFuelCorrection()

| float getIatFuelCorrection | ( | ) |

Definition at line 395 of file fuel_math.cpp.

Referenced by EngineState::periodicFastCallback().

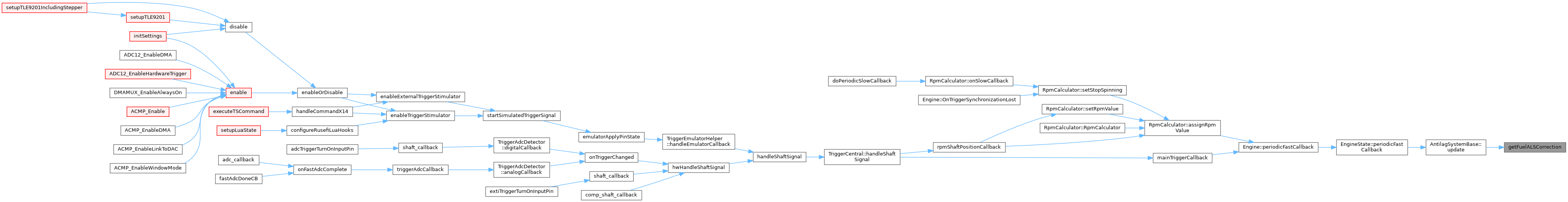

◆ getInjectionMass()

- Returns

- Mass of each individual fuel injection, in grams in case of single point injection mode the amount of fuel into all cylinders, otherwise the amount for one cylinder

Definition at line 312 of file fuel_math.cpp.

Referenced by EngineState::periodicFastCallback().

◆ getInjectionModeDurationMultiplier()

| float getInjectionModeDurationMultiplier | ( | ) |

Definition at line 263 of file fuel_math.cpp.

Referenced by getInjectionMass().

◆ getInjectionOffset()

Definition at line 217 of file fuel_math.cpp.

Referenced by EngineState::periodicFastCallback().

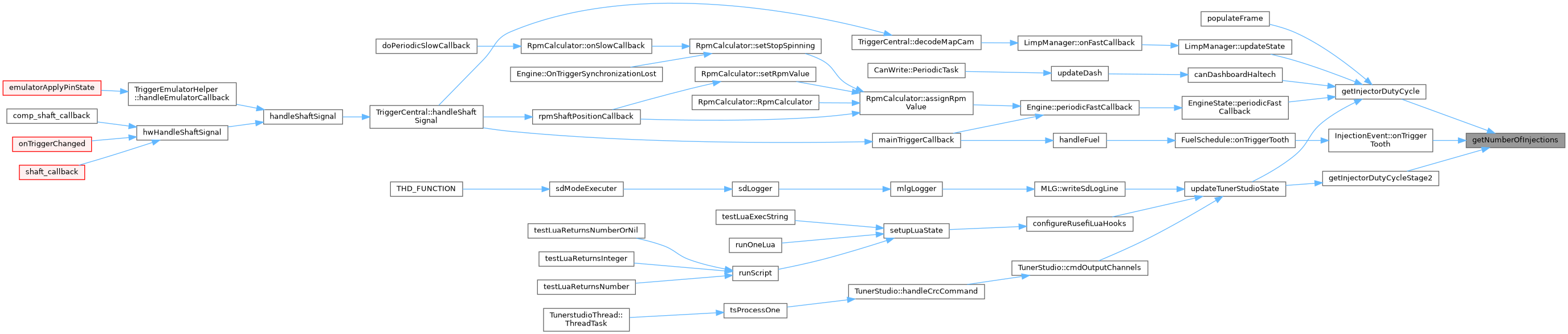

◆ getInjectorDutyCycle()

Definition at line 288 of file fuel_math.cpp.

Referenced by canDashboardHaltech(), EngineState::periodicFastCallback(), populateFrame(), LimpManager::updateState(), and updateTunerStudioState().

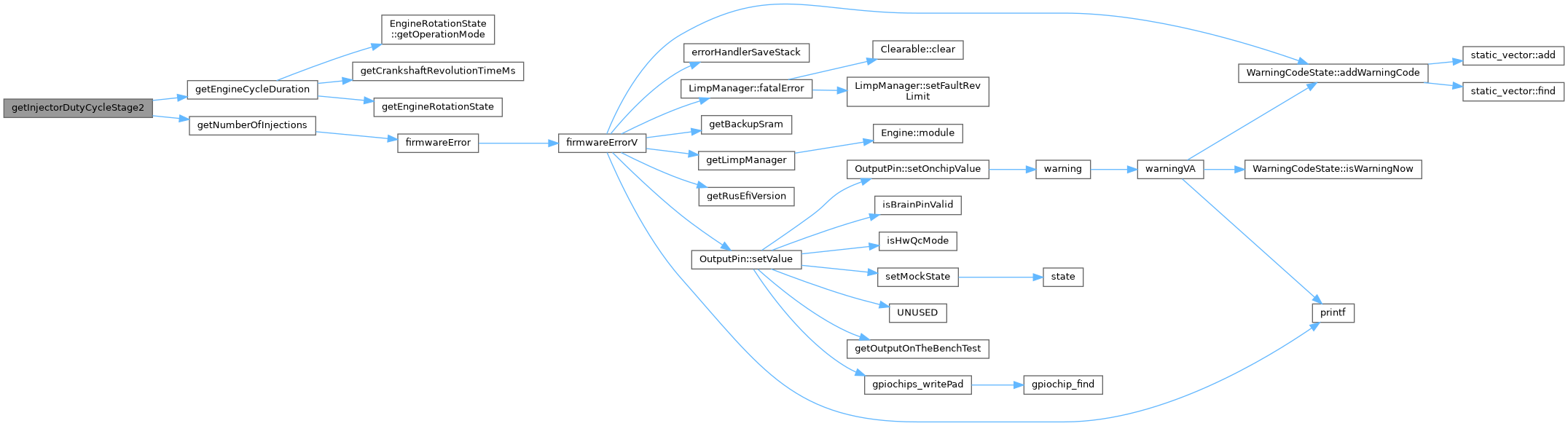

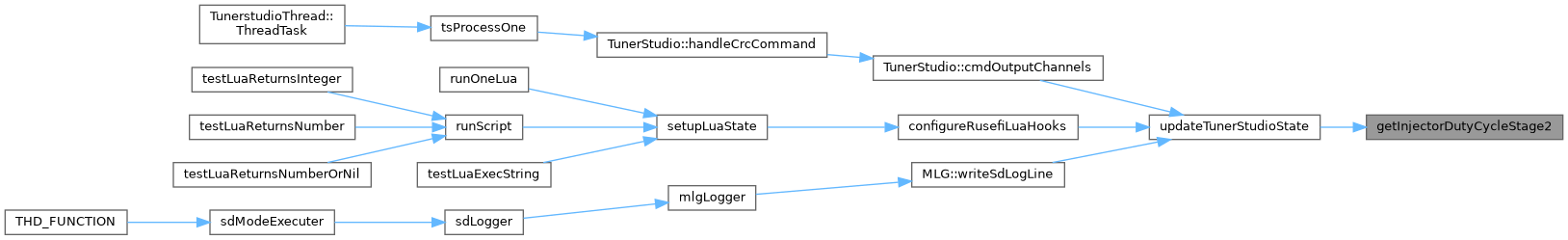

◆ getInjectorDutyCycleStage2()

Definition at line 294 of file fuel_math.cpp.

Referenced by updateTunerStudioState().

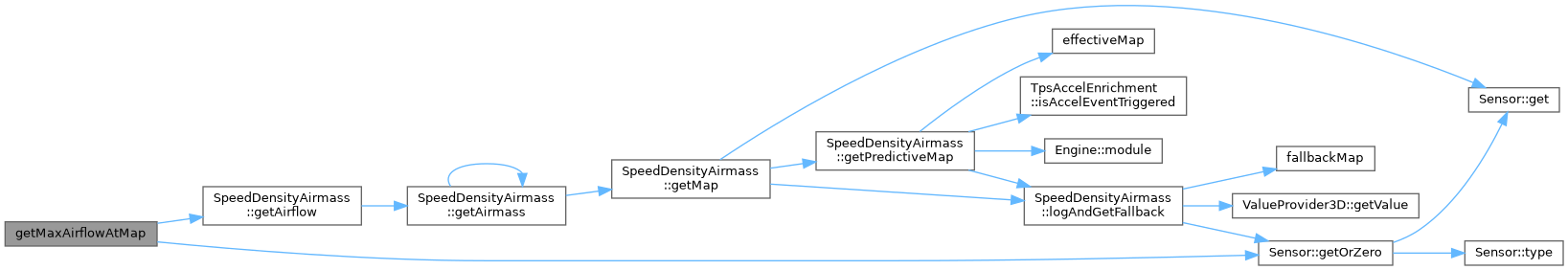

◆ getMaxAirflowAtMap()

Definition at line 176 of file fuel_math.cpp.

Referenced by ThrottleModel::maxEngineFlow().

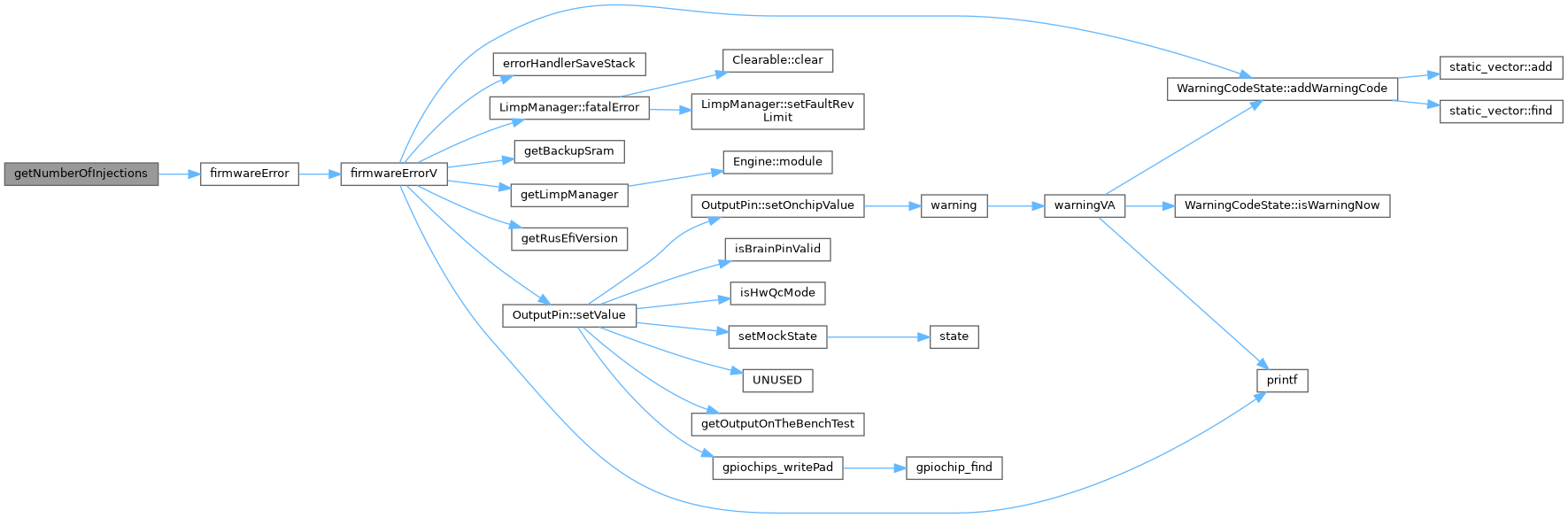

◆ getNumberOfInjections()

| int getNumberOfInjections | ( | injection_mode_e | mode | ) |

Number of injections using each injector per engine cycle

- See also

- getNumberOfSparks

Definition at line 248 of file fuel_math.cpp.

Referenced by getInjectorDutyCycle(), getInjectorDutyCycleStage2(), and InjectionEvent::onTriggerTooth().

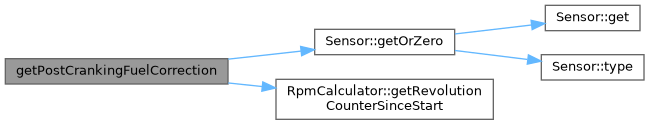

◆ getPostCrankingFuelCorrection()

| float getPostCrankingFuelCorrection | ( | ) |

Definition at line 404 of file fuel_math.cpp.

Referenced by EngineState::periodicFastCallback().

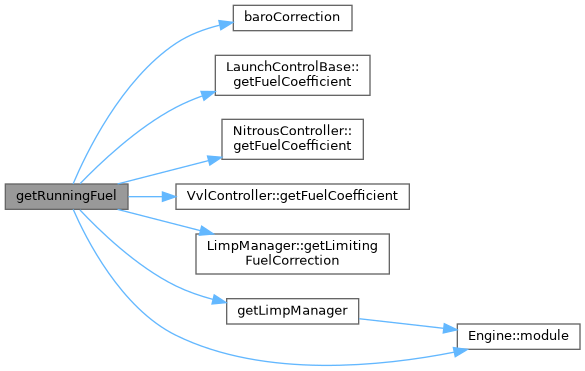

◆ getRunningFuel()

- Returns

- baseFuel with CLT and IAT corrections

Definition at line 111 of file fuel_math.cpp.

Referenced by getCycleFuelMass().

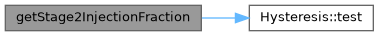

◆ getStage2InjectionFraction()

Definition at line 506 of file fuel_math.cpp.

Referenced by EngineState::periodicFastCallback().

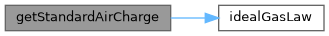

◆ getStandardAirCharge()

| float getStandardAirCharge | ( | ) |

Standard cylinder air charge - 100% VE at standard temperature, grams per cylinder

Should we bother caching 'getStandardAirCharge' result or can we afford to run the math every time we calculate fuel?

Definition at line 481 of file fuel_math.cpp.

Referenced by MafAirmass::getAirmassImpl(), and getBaseFuelMass().

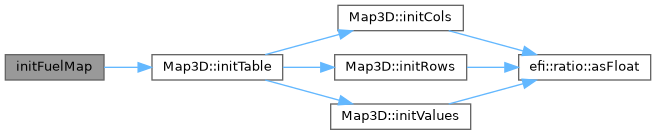

◆ initFuelMap()

| void initFuelMap | ( | ) |

Initialize fuel map data structure.

- Note

- this method has nothing to do with fuel map VALUES - it's job is to prepare the fuel map data structure for 3d interpolation

Definition at line 379 of file fuel_math.cpp.

Referenced by initDataStructures().

Variable Documentation

◆ alphaNAirmass

|

static |

Referenced by getAirmassModel().

◆ mafAirmass

|

static |

Referenced by getAirmassModel().

◆ mapEstimationTable

|

static |

◆ sdAirmass

|

static |

Referenced by getAirmassModel(), and getMaxAirflowAtMap().

◆ stage2Hysteresis

|

static |

Definition at line 504 of file fuel_math.cpp.

Referenced by getStage2InjectionFraction().

◆ veMap

|

extern |